Case Study 03

Lean Store/VLM SAP Integration for FIFO Management in Warehouse Automation

Overview

A global manufacturing company specializing in high-precision automotive components. The company operates multiple warehouses that support Just-In-Time (JIT) production to keep the assembly lines running efficiently. However, maintaining FIFO, tracking physical stock, and ensuring inventory accuracy in a timely manner have been persistent challenges.

Problem Statement

- FIFO Compliance :Manual tracking often led to incorrect stock rotation, resulting in expired parts being used and production delays.

- Daily Physical Stock Counting: Operators spent significant time manually reconciling physical stock with system data.

- Space Constraints: Traditional storage methods resulted in inefficient space usage and frequent manual picking errors.

- SAP Integration: Lack of real-time synchronization with SAP led to stock mismatches between the system and warehouse floor.

- Labor Costs: High reliance on manual effort increased operational costs.

Objectives

- Automate inventory management through Lean Store/VLM (Vertical Lift Module) or Vertical Carousel systems.

- Integrate with SAP for real-time stock updates.

- Enforce FIFO to avoid expired or obsolete stock being used in production.

- Eliminate manual stock counting and reduce discrepancies.

- Maximize storage efficiency through vertical automation.

- Enhance production planning with real-time and accurate inventory data.

- Enable user-wise access controls, track operator/machine performance, and automate error handling.

Solution: Lean Store/VLM & Vertical Carousel Integration with SAP

Key Features and Software Highlights

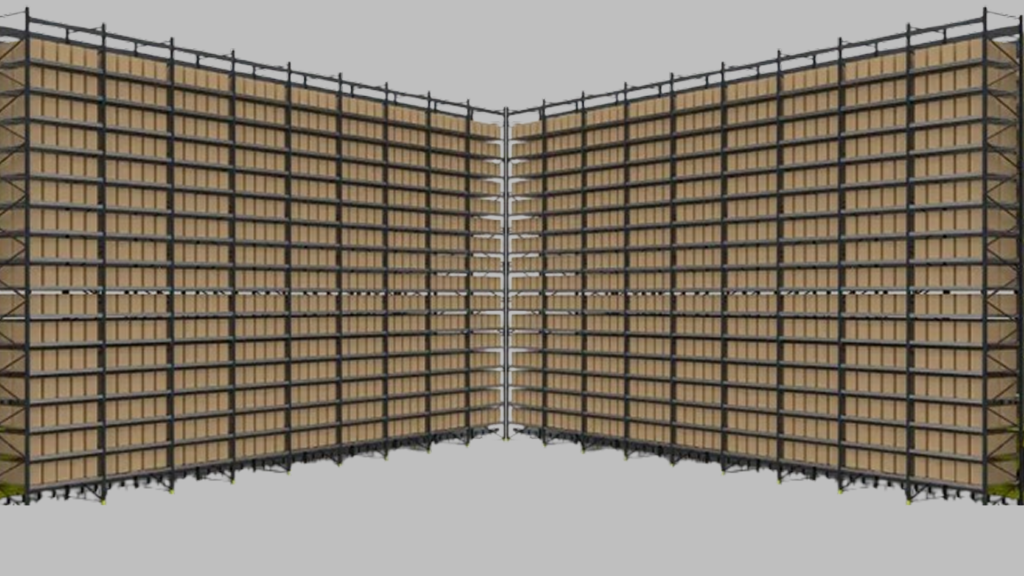

Vertical Lift Module (VLM) / Vertical Carousel

- Compact, automated systems store and retrieve parts vertically, maximizing space.

- Faster retrieval reduces walking time and improves operational efficiency.

- FIFO logic ensures older stock is picked first automatically.

SAP Integration

- Real-Time Data Sync: Stock levels, receipts, and retrievals are updated instantly in SAP.

- Material Management Updates: SAP reflects the most accurate stock positions after each operation.

- Auto Stock Adjustments: System updates SAP after every transaction without manual intervention.

FIFO and Batch Tracking

- Items are stored with associated batch numbers and timestamps.

- Automated logic ensures the oldest part is always retrieved first.

- Expired stock usage is fully prevented.

Physical Stock Calculation

- VLM-integrated sensors and barcode/RFID tracking continuously monitor actual inventory.

- Eliminates need for daily physical checks — system stock is always in sync with real stock.

Andon System for Monitoring

- Large displays provide real-time visibility of:

- Stock levels

- FIFO status

- Retrieval progress

- Machine availability

Advanced Operational Features

User-Wise Access Control:

- Role-based access ensures different permission levels (operator, supervisor, admin).

- Activity logs are maintained per user.

Weight Management:

- Real-time weight checks during inbound/outbound ensure correct item quantity.

- Prevents mismatch errors and unauthorized retrievals.

Machine Error Handling:

- All system faults are logged with timestamps and error codes.

- Auto-notifications sent to maintenance or supervisors.

- Downtime tracking available for root cause analysis.

Performance Monitoring:

- Operator Efficiency: Tracks items picked/stored, error rates, and speed.

- Machine KPIs: Measures tray access time, retrieval speed, and uptime/downtime reports.

- Enables continuous improvement using performance analytics.

Workflow Overview

Inbound (Automated Storage)

- Items scanned at entry using barcode/RFID.

- VLM auto-assigns optimal slot based on FIFO logic and part type.

- Stock location and timestamp updated in SAP instantly.

Storage & Inventory Management

- Based on JIT requests from SAP, VLM retrieves items in FIFO order.

- Live updates pushed to SAP after every movement.

- No manual intervention or confirmation needed.

Physical Stock Calculation

- VLM sensors + RFID/barcode integration provides precise live stock visibility.

- Continuous background sync with SAP.

- No need for cycle counting by floor staff.

Outbound (Production Supply)

- SAP triggers JIT call for required items.

- VLM retrieves correct batch in FIFO order.

- Delivered directly to production with quantity and batch auto-logged.

Benefits

- Real-Time Inventory Sync with SAP: Eliminates data mismatches.

- Efficient FIFO Handling: No manual sorting required—100% automatic.

- Space Optimization: Utilizes vertical space to double storage capacity.

- Labor Savings: Automation reduces manual intervention drastically.

- Operator/Machine Performance Insights: Enables accountability and productivity tracking.

- Reduced Errors: Real-time checks on weight, movement, and location eliminate picking mistakes.

- Machine Health Monitoring: Error history and recovery logs ensure long-term system stability.

Lessons Learned

- SAP ↔ VLM Communication Must Be Real-Time: Lag causes discrepancies.

- High-Demand Parts Should Be Prioritized in Retrieval Paths.

- User Access Rights Should Be Configurable and Audited.

Discover how LogiArk can streamline your warehouse with ASRS, WMS, and automation tools tailored to your operations.